|

|

Product |

Description |

Price |

|

4890 |

Concrete Finishing Overshoes For Shoes & Boots Sizes

8 to 13 |

Out

Of Stock |

|

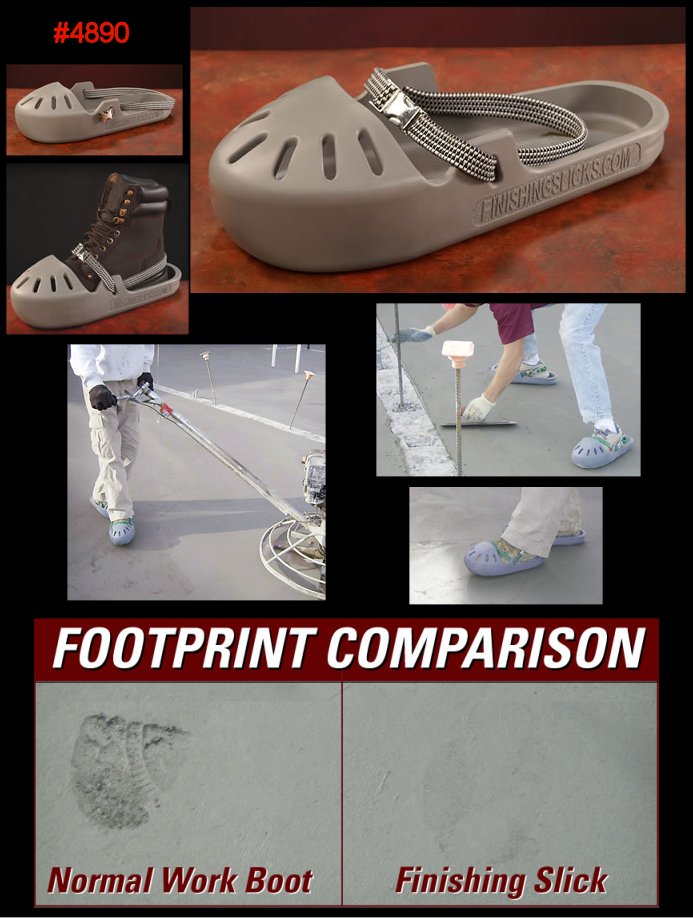

CONCRETE INNOVATIONS - ONE PAIR FINISHING SLICKS BRAND CONCRETE FINISHING OVERSHOES FINISHING SLICKS™ Brand Concrete Finishing Overshoes are designed to be worn during the actual finishing phase of concrete. FINISHING SLICKS™ eliminate the need of patching up holes and marks, which normally work boots/shoes and knee boards would leave behind. By eliminating repetitious motion, FINISHING SLICKS™ will save the concrete finisher time and money, while still allowing for quality. Product Features: FINISHING SLICKS™ Brand Concrete Finishing Overshoes should be a standard tool for every concrete finisher, as intricate as the float. FINISHING SLICKS™ Brand Concrete Finishing Overshoes will increase productivity, by removing common obstacles caused by wearing regular work shoes, thus eliminating unnecessary and repetitious motion, thus saving time, energy and money. FINISHING SLICKS™ allow you to walk on concrete surfaces as they dry without leaving the deep marks normally experienced with workboots and kneeborads. This allows you to finish more concrete faster than ever. The image above shows the difference between a footprint in wet concrete. Note the deep impressions made by the boot on the left versus those left by the FINISHING SLICKS™ on the right. FINISHING SLICKS™ Brand Concrete Finishing Overshoes fit over your normal work boots to allow you to finish concrete without having to change shoes. Simply slide your shoe under the strap, and secure the latch with the strap behind your heel. Working while wearing FINISHING SLICKS™ Brand Concrete Finishing Overshoes, saves time and money by virtually eliminating the creation of foot prints in the semi-hardened concrete. FINISHING SLICKS™ Brand Concrete Finishing Overshoes are designed to work

with nearly any shoe or boot from sizes FINISHING TIPS: I am Rodney Coomer, inventor of Finishing Slicks™ Brand Over Shoe. I have been in the concrete finishing trade for 25 years. I started out in residential concrete finishing and eventually moved into the commercial and industrial phase of concrete finishing, which I have been doing for the last 13 years. I have placed and finished as much as 1,250,000 square feet in a years time. The reasoning behind the invention of the Finishing Slicks™ Brand Over Shoe came from the burden of having to patch and fill in holes and marks that were left behind from work boots and shoes worn by finishers. Majority of finishers use knee boards, to try to eliminate the problem of having to fill and patch footprints and shoe impressions, which causes a lot of time and is back-breaking work. When I finished residential, my step-father who taught me how to finish, always had me on knee boards around the edges and pipes during the entire finishing stage. As I finally became good enough to finish on my own I used knee boards on the first float and after that I started walking on the concrete slab to finish edges and pipes. I then would use a trowel machine to fill in holes left behind from the work boot right after the edges were worked. This technique gave me an advantage by making up a lot of time and thus I covered all the edges faster than using knee boards, however I still had holes and marks being left from my work boots. I also discovered, when walking on a surface I was finishing, that was poured with air-entrained concrete, the surface was very sticky and the top pulled up easily leaving behind holes, which had to be filled. I have tried, as I know you have too, a variety of products: plastic, cardboard, flip flops and even grounding off the bottom of work shoes, to name a few, in eliminating this problem. With nothing being successful I have had to fight this problem for years. Here is my technique that has worked successfully using the Finishing Slicks™ Brand Over Shoe. Now, when I finish slabs I let my finishers go over the edges and pipes the first and sometimes the second float, using knee boards. When the slab is firm enough to be stood on (without sinking) and ready to start troweling, my finishers will put on their Finishing Slicks™ Brand Over Shoe and finish the edges and pipes faster, not leaving holes and marks that normally work boots or shoes would leave behind. A lot of testing of different materials went into the Finishing Slicks™ Brand Over Shoe, to insure that the Finishing Slicks™ would not adhere to most concrete surfaces. SUGGESTED PROCEDURES FOR USE AND CARE OF FINISHING SLICKS™ 1. Let the finisher go in front of your trowel machine and work his edges, then have your trowel machine operator go over what minimum impressions that are left behind by the Finishing Slicks™. 2. Never walk on a newly troweled surface, especially if it is subject to air-entrained concrete. 3. Whenever possible, use a NON air-entrained concrete mix when troweling a hard troweled finished surface, that is not subject to freezing and thawing. Check with your local ACI standards and codes. 4. During the finishing phase, water is sometimes thrown on the floor to help aid in retarding finishing. Even though finishing slicks have been tested for adequate traction under wet conditions. Use caution while applying water during finishing process, while wearing finishing slicks. 5. The Finishing Slicks™ Brand Over Shoe will be a great necessity to the finisher using a walk behind trowel machine, eliminating the need of re-troweling over their own boot/shoe marks. 6. Remember to wash and keep your Finishing Slicks™ clean. Clean only with water and using a soft brush immediately after use for best results. Do NOT use abrasive materials such as wire brushes, margin trowels or hand trowels to clean bottom of Finishing Slicks™. Do not use any chemicals to clean your Finishing Slicks™. Don’t walk on rocks and sharp objects while wearing the Finishing Slicks™. Use them only on cement based surfaces. This will help extend the life of your Finishing Slicks™. Using the Finishing Slicks™ Brand Over Shoe with these tips and techniques will enable you to finish edges and slabs faster with less man power. This will also make it easier on your trowel machine operator. INSTRUCTIONS FOR USING FINISHING SLICKS™ Brand Over Shoes 1. Position the strap as shown in Photo That’s it, you have now securely attached the Finishing Slicks™ Brand Over Shoe, to your work boot. Now you are ready to save time and money on your next concrete finishing job! |

Home | Product Lines

| Instructional

Items | Contact Us

E-Mail

Us: masonryplus@capcityequipment.com

Copyright

© 1991-2015 Capitol City Scaffolding & Equipment Company, Inc. All rights

reserved.

Services, prices, and terms subject to change without notice.