|

OPERATING

INSTRUCTIONS

1) Some grouts are more difficult (or impossible) to pump than

others.

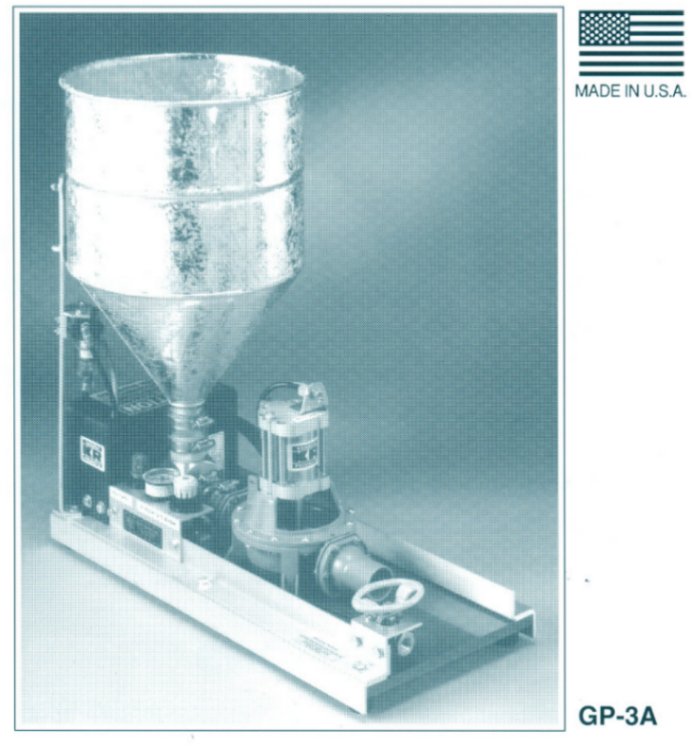

2) Check that the "ball valve" (yellow oval handle) and the

"stop/start switch" (brass switch on top of cylinder) are both

turned to "off" position.

3) Attach an air source from your compressor to the "ball

valve".

4) The "pressure control" is the yelow round knob.

Turn clockwise to increase pressure, counterclockwise to decrease

pressure. Normal operating pressure is 30 psi. Never adjust

pressure above 50 psi to avoid damage to pump. As a reference, grout

line pressure is approximately 1/3rd of what is shown on the air gauge (i.e.

30 psi on gauge would indicate 10 psi grout line pressure). If air

pressure is adjusted below 20 psi, pump will not cycle.

5) The "speed control" is a black knob with a red ring.

Turning it clockwise will slow the cycle speed, counterclockwise speeds

the cycle speed. It is a good idea to start the pump slowly, then

increase the cycle speed after the grout has started to flow from the end of

the placement hose.

6) With the air supply hose connected abd the "ball valve"

turned on, the pump can then be started and stopped from the

"stop/start" switch on top of the air cylinder.

7) Place grout in a suitable container and mix per manufacturers

recomendations. Pour mixed grout mixture into hopper. Some

grouts, such as Fosroc Renderoc LA, require that the pump be primed with a

cement/water slurry.

8) Start pump using the "start/stop" switch. Adjust

pressure and speed controls as required. CAUTION: VERY MINIMAL PUMP

PRESSURE IS REQUIRED TO FILL VOIDS WITH GROUT.

9) Be sure the work area is vented to allow any trapped air to escape.

10) Do not allow the grout to harden while inside or on the outside of

the pump or related components. Clean immediately after use.

11) This pump is designed to be used with water based grouts only.

It is not to be used to pump chemical based epoxy grouts.

12) When servicing the pump, be sure to remove the air supply hose

and turn off the "ball valve" to depressurize the system.

|